Everest Cement Fiber Board

Cement, cellulose fibers, and mineral additives are combined to create Everest Cement Fibre Board, a high-performance, multipurpose building material. These boards, which are perfect for both indoor and outdoor applications like wall partitions, ceilings, cladding, and flooring, are made with strength, durability, and dimensional stability in mind. Everest boards can be used in humid and difficult environments because of their resistance to weather, termites, fire, and moisture.

| Brand / Type | Everest Fibre Cement Board (Multipurpose & Heavy Duty variants) |

| Standards | IS 14862:2000 Type A (Category IV) for Heavy Duty; Type B (Category III) for Multipurpose |

| Dimensions | 2440 × 1220 mm (also other sizes like 3050×1220, 1830×1220, 1220×1220) |

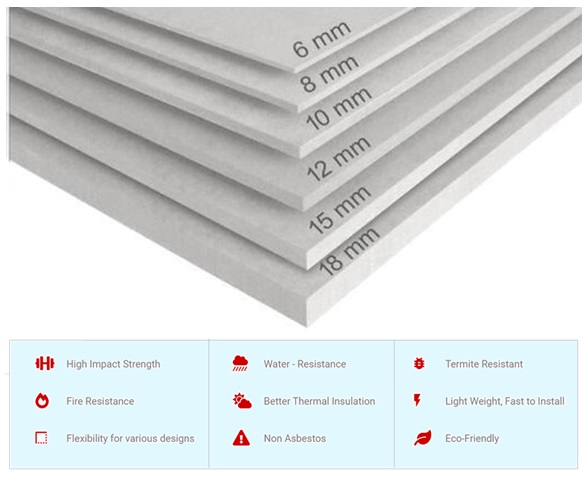

| Available Thickness | Multipurpose: 6–18 mm; Heavy Duty: 6, 9, 12, 15 mm (up to 18 mm possible) |

| Apparent Density | Multipurpose: > 1200 kg/m³; Heavy Duty (HDF/SuperHD): > 1450 kg/m³ |

| Weight | ~8.9 kg/m² for 6 mm Multipurpose; ~10.2 kg/m² for 6 mm Heavy Duty |

| Modulus of Rupture (Dry / EMC) | Heavy Duty: ≥ 18 MPa at EMC; > 14 MPa (wet) per ASTM C 1185 |

| Screw Withdrawal Strength | > 1750 N (ASTM D 1037) |

| Modulus of Elasticity | ≥ 4000 MPa per EN 12467 |

| Thermal Conductivity (at ~50 °C) | ≈ 0.22 W/m·K (for Heavy Duty); Multipurpose ≈ 0.087 W/m·K |

| Water Absorption | < 26%; Heavy Duty around < 30% |

| Fire Classification | Reaction to Fire: EN 13501‑1 A2‑s1‑d0; non‑combustible BS 476 Part IV; passes Parts VI/VII; Class 1 flame spread |

| Acoustic Insulation | Heavy Duty: ~32 dB (6 mm); Multipurpose: ~26 dB (6 mm) |

| Composition | Cement, cellulose fibre, silica/quartz, mineral fillers (100% asbestos-free) |

| Key Features | Impact‑resistant, moisture‑resistant, fire‑resistant, weather‑resistant, termite‑proof, sound‑insulating, eco‑friendly, GreenPro certified |

| Typical Applications | External cladding, facades, partitions, ceilings, wet‑area linings, mezzanine floors, duct encasements, load‑bearing substrates |

Shera Cement Fiber Board

A blend of cement, cellulose fibers, and silica is used to create Shera Cement Fibre Board, an eco-friendly, high-quality building material that is autoclaved at high pressure for exceptional strength and durability. Shera Boards are well-known for their exceptional resistance to weathering, fire, moisture, and termites.

| Composition | Portland cement, cellulose fibre, refined sand; autoclave‑cured; asbestos‑free |

| Standards / Certification | CE marked to EN 12467; ASTM C1185/1186; BS 476; A1 reaction‑to‑fire (non‑combustible) |

| Dimensions (mm) | Typically 1200 × 2400; other sizes on request |

| Thickness Options | 4 mm, 6 mm, 8 mm, 9 mm, 10 mm, 12 mm, 15 mm, 16 mm (boards & decorative variants) |

| Weight (approx.) | 6 mm ~27 kg; 8 mm ~36 kg; 9 mm ~40.5 kg; 10 mm ~45 kg; 12 mm ~54 kg; 15 mm ~66 kg per panel |

| Density | ~1350 ± 50 kg/m³ |

| Flexural Strength (Wet) | > 7 MPa |

| Modulus of Elasticity (Wet) | ~3000–5500 MPa |

| Water Absorption | < 35%< /td> |

| Moisture Content | < 12–15%< /td> |

| Dimensional Movement | Moisture movement ≤ 0.04%; length change < 0.1%< /td> |

| Thermal Conductivity | ~0.15 W/m·K |

| Acoustic Performance | STC ≈ 30 dB (single 6 mm); 50–60 dB composite wall |

| Fire Performance | A1 reaction to fire; BS 476 tests passed; non‑combustible |

| Durability | Freeze‑thaw, warm‑water, soak‑dry, heat/rain resistance all passed (> 0.75 rating) |

| Applications | External/internal wall cladding, partitions, wet zones, tile base, ceilings, façades |

| Key Benefits | Fire‑resistant, weather‑proof, moisture‑resistant, termite‑proof, sound‑insulating, low shrinkage, durable |

Hilux Calcium Silicated Board

Ramco Industries produces Hilux Calcium Silicate Board, a long-lasting, non-flammable building material intended for high-performance indoor and outdoor applications. Composed of cement, silica, and cellulose fibers, the board is made with cutting-edge HPSC (High-Pressure Steam Curing) technology and provides exceptional resistance to moisture, fire, termites, and fungal growth.

| Material | Fiber-reinforced calcium silicate |

| Thickness | 6 mm to 16 mm |

| Board Size | 2440 × 1220 mm |

| Density | ~900 kg/m³ |

| Fire Resistance | Up to 4 hours |

| Applications | Walls, ceilings, cladding, wet areas |

Readymade Wall Panel

Readymade wall panels are prefabricated wall solutions made to be built quickly, neatly, and effectively. They provide outstanding durability, thermal insulation, and soundproofing qualities and are made from materials such as composite panels, gypsum, cement board, or Aerocon. These panels are perfect for both residential and commercial settings because they are strong yet lightweight, simple to install, and require little work or curing time.

| Material | Fibre Cement / AAC / Gypsum |

| Thickness | 50–75 mm |

| Size | 8×4 ft approx |

| Applications | Internal & External Walls |

| Benefits | Lightweight, Fast Installation |

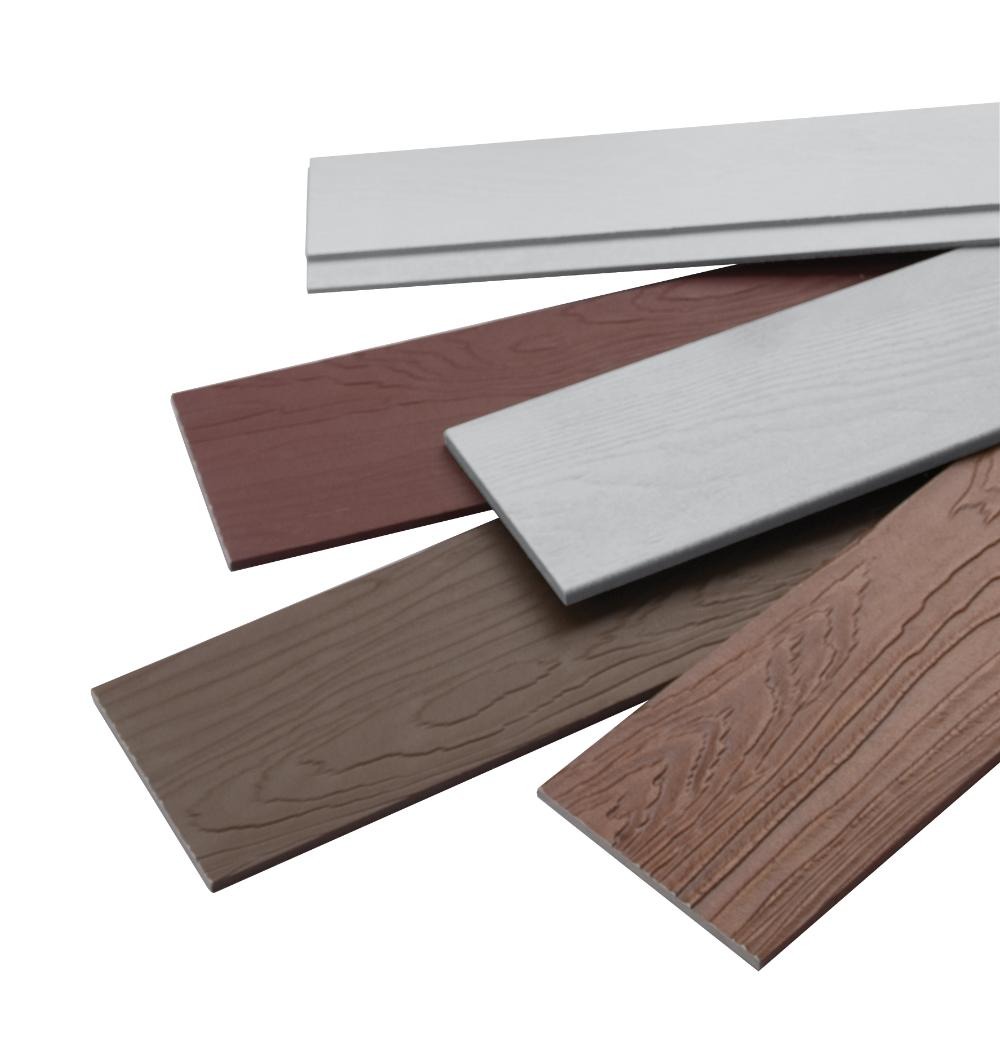

Fiber Cement Plank Wall Cladding

Fiber Cement Plank Wall Cladding is a durable and aesthetically pleasing exterior and interior wall solution made from a composite of cement, cellulose fibers, and silica. It offers a natural wood-like finish while providing superior resistance to moisture, fire, termites, and harsh weather conditions. Ideal for modern and traditional architecture, these planks are low-maintenance, long-lasting, and perfect for enhancing the visual appeal of both residential and commercial buildings.

| Parameter | Specification |

|---|---|

| Material Composition | Cement, cellulose fibers, silica, and additives |

| Standard Thickness | 6 mm, 8 mm, 10 mm (others on request) |

| Standard Width | 150 mm to 300 mm |

| Length | 2440 mm / 3050 mm |

| Finish | Textured / Wood grain / Smooth |

| Fire Resistance | Class A / Non-combustible |

| Water Resistance | Highly moisture resistant |

| UV Resistance | Excellent, suitable for outdoor use |

| Application | Exterior & interior wall cladding, facades, soffits |

Texture Board

Decorative wall panels called texture boards are made to add visual interest, depth, and pattern to surfaces inside or outside. These boards, which are made from materials like MDF, gypsum, PVC, WPC, or fiber cement, have carved or embossed textures like wood grains, geometric shapes, stone finishes, or wave patterns.

| Material | Fiber‑cement (autoclaved, asbestos‑free) |

| Thickness | ~7.5 – 8 mm |

| Panel Size | ≈600×1200 mm, 1220×2440 mm |

| Texture Options | Brick‑grain, wood‑grain planks, grooved patterns |

| Key Features | Weather‑resistant, termite‑proof, impact‑resistant, decorative |